Ecorevive is spread over an area of 12.000 square meters of which approximately 4,000 are covered. The area has been organized to keep waste/secondary raw material flows separate. Waste storage, preparation and recycling operations all take place in covered areas to minimize environmental impacts.

Particular attention is paid to the environment: Ecorevive does not use water for its recycling process and emissions are constantly monitored.

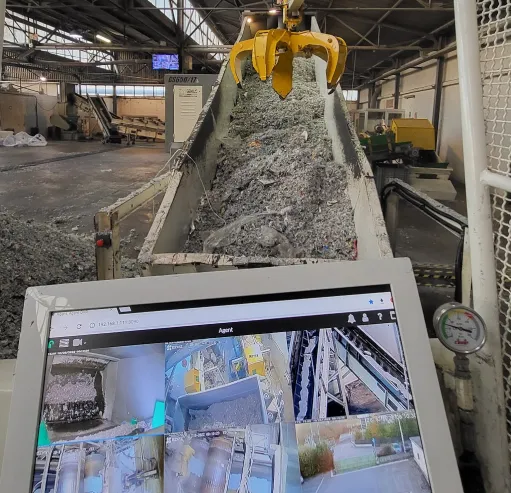

Ecorevive has developed a continuous agglomeration process, with which it is able to recycle different types of plastic waste, even if containing high percentages of humidity.

The line is completed with shredders, belts, de-metallizers and dust collectors to guarantee a constant quality of the final products. The result is a completely degassed agglomerated granule with technical characteristics that allow it to be used as a replacement for classic granules.

Ecorevive has developed its own software for the targeted management of process subsystems.

All process phases, material acceptance, production and warehouse management as well as energy consumption are monitored.

Smart production, service and energy, are the key terms for achieving industrial standards to which Ecorevive remains faithful, through the use of new production technologies that create collaboration between all the elements mentioned.

We monitor our energy consumption, reducing waste according to the typical paradigms of Sustainable Energy and Circular Economy.